The motor bearing is a very important part of the motor, responsible for supporting and protecting the motor's rotor and allowing it to rotate smoothly within the bearing. Motor bearings typically consist of an inner and outer ring, rolling elements, a cage, and a sealing ring.

The inner ring is fixed to the motor shaft, while the outer ring is fixed to the motor housing. The rolling elements are located between the inner and outer rings, supporting and driving the rotor rotation, typically made of steel balls. The cage is used to hold the rolling elements in place and maintain their position and direction within the bearing. The sealing ring can prevent dust and moisture from entering the bearing, ensuring the lifespan of the motor bearing.

When selecting motor bearings, factors such as the motor load, speed, rotor weight, and inertia, as well as the rated load, maximum speed, and applicable temperature of the bearing, must be considered to ensure that the bearing meets the requirements of the motor. Additionally, regular maintenance and upkeep, such as cleaning and lubrication, are necessary to ensure the proper functioning and lifespan of the motor bearings during operation.

The precision deep groove ball bearings produced by Wuxi Jierte Bearing Co., Ltd. are designed for high precision, low noise, small vibration, high reliability, and long life. They are mainly used in various types of electric motors. They are also known as EMQ (Electric Motor Mass) bearings. With optimized designs, high-reliability heat treatments, sophisticated manufacturing processes, and advanced greases, these products outperform standard products in reliability, vibration, and noise levels, making them more suitable for motor applications. These products can also be used in most gearbox applications.

We provide OEM, ODM, and other services, and provide you with relevant consulting information to help you with bearing selection, clearance configuration, product life, and reliability analysis. We offer localized shipping solutions to save your shipping costs.

What are our advantages?

(1) Advanced production equipment

(2) Strong technical force

(3) High production capacity

(4) Short delivery time

(5) Low MOQ

(6) Strict quality control

(7) Competitive price

(8) ISO9001:2018 certification

Inner ring and outer ring: imported material requirements, fine grinding, full inspection, black chamfer import process;

Steel ball: high-quality high grade steel ball;

Sealing ring: ZZ, stamped steel plate, high-speed operation, no printing can be customized;2RS, made of rubber, dustproof and waterproof, no printing can be customized;

Grease: fully meets standard grease loading;

Cages: Steel stainless steel, brass or PEEK cages can be used at the same operating temperatures as the bearing rings and balls. For temperature limits of cages made of other polymer materials, refer to Polymer cages.

Seals: The perissible operation temperature for seals depends on the seal material.

NBR:-40 to +100 ºC (-40 to -210 ºF)

Temperatures up to 120 ºC (250 ºF) can be tolerated for bried periods.

FKM:-30 to +200 ºC (-20 to +390 ºF)

Temperatures up to 230 ºC (445 ºF) can be tolerated for brief periods.

We produce motor bearing have the following characteristics:

1. High-speed rotation:

2. High-temperature resistance:

3. Long life:

4. Low friction:

5. Quiet operation:

6. High precision requirements:

We produce motor bearing mainly through the following steps:

1. Material preparation: Motor bearings are typically made from high-hardness, high-strength metal materials. In the production process, the raw materials need to be cut into appropriately sized round blanks.

2. Cold extrusion forming: The formed blanks are made into rough bearings parts through cold extrusion. This step mainly involves shaping the metal material into the preliminary shape of bearing parts, including outer rings, inner rings, and balls, through the pressure of a cold extrusion machine and the action of molds.

3. Heat treatment: Changing the metal material's structure and properties through heating and cooling to improve the bearing's hardness, strength, wear resistance, and corrosion resistance. Heat treatment includes quenching, tempering, normalizing, etc.

4. Precision machining: Bearing parts are precisely machined through processes such as turning, milling, and grinding to achieve high precision and low noise requirements.

5. Assembly and lubrication: Assemble the precision machined bearing parts and inject lubricating oil or solid lubricant. The assembly process needs to ensure the matching precision of the bearing parts and the uniformity of lubrication to ensure the normal operation and long life of the bearing.

6. Testing: Quality testing and measurement of bearing parts are required at various stages of the production process, including dimensional accuracy, roundness, flatness, noise, and other indicators.

7. Packaging and shipping: The motor bearing that has undergone quality inspection need to be packaged to protect them from damage. Common packaging materials include cartons, wooden boxes, and pallets. Finally, the products can be shipped to customers by sea, air, or land transportation.

Motor Bearing production video

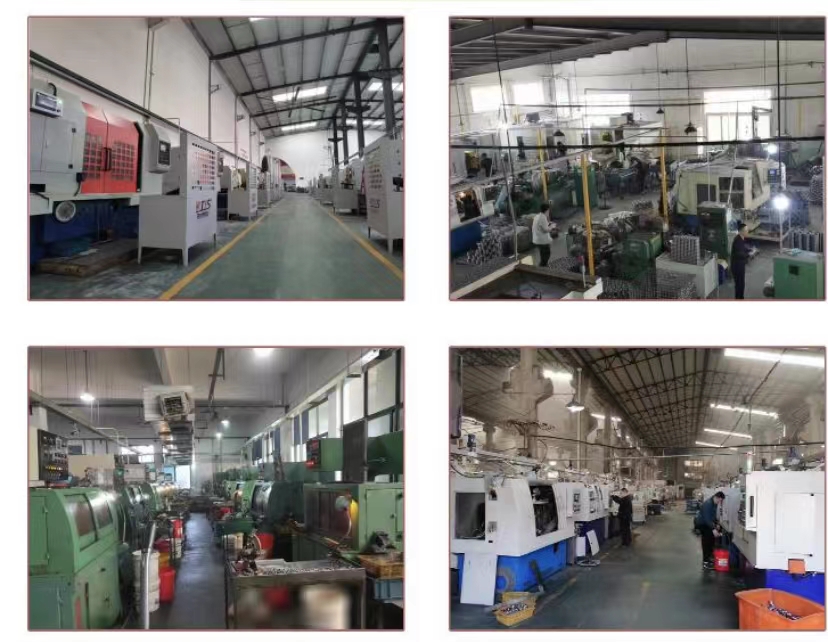

Production Workshop

Q1: Are you a trading company or a manufacturer?

A1: We are a manufacturer.We have our own factory ;our type is factory +trade

Q2: How long is your delivery time?

A2: Generally it is 15-20 days, if the goods are in stock, it is 3-7 days, if the goods are not in stock, it depends on the quantity.

Q3: Do you provide samples? Is it free or extra?

A3: Yes, we can provide samples for free, but we don't pay shipping fee.

Q4. How do you control the quality,and what if there is quality problem?

A4: All bearings will be 100% strictly inspected before shipment, including hardness, size, noise, speed, vibration and accuracy. If there is any quality problem, we will replace all faulty products with our shipping cost or refund to you.

Q5:OEM and customized can you accept?

A5: Yes, OEM is accepted, also can be customized for you according to samples or drawings

Q6: What are your shipping conditions.

A6: We can arrange shipping by sea to your nearest seaport or deliver to your doorstep. Air freight is also possible. We can help with all import formalities. It takes about 25-40 days by sea and 3-7 days by air.

Contact: Zhang lianjie

Phone: +86 13771539960

E-mail: jason@jetbearing.com

Whatsapp:+86 13771539960

Add: No.25, Guangtai Industry Park, Xishan District, Wuxi City, Jiangsu Province, China

Contact: Zhang lianjie

Phone: +86 13771539960

E-mail: jason@jetbearing.com

Whatsapp:+86 13771539960

Add: No.25, Guangtai Industry Park,Xishan District, Wuxi City, Jiangsu Province, China

We chat