Spherical roller bearings have double row rollers, the outer ring has a shared spherical raceway, and the inner ring has two raceways, which are inclined at an angle relative to the bearing axis. This ingenious structure makes it self-aligning, so it is not easily affected by the angle between the shaft and the housing seat on errors or shaft bending. The spherical roller bearing is a rolling bearing that allows rotation, with low friction and high impact resistance. , Anti-vibration, mainly bear large radial load, can also bear appropriate axial load, etc.

Wuxi Jieerte Bearing Co., Ltd. is a professional bearing manufacturer. The company has 20 production lines for bearings, with a daily output of 100,000 sets. Its quality and environmental management system have passed ISO 9001 and ISO 14001 certification. The company has its own brand "JSJET" and also provides OEM services. Our products are known for their high precision, low noise, long service life, and stable performance. They are widely used in various industries such as motors, water pumps, automobile transmissions, motorcycle engines, conveying systems, agricultural machinery, mining equipment, and construction machinery.

What are our advantages?

(1) Advanced production equipment

(2) Strong technical force

(3) High production capacity

(4) Short delivery time

(5) Low MOQ

(6) Strict quality control

(7) Competitive price

(8) ISO9001:2018 certification

We produce spherical roller bearing have the following characteristics:

1. Can withstand large radial and axial loads

2. Can adjust the self-deviation of the bearing:

3. Easy to install and disassemble:

4. Suitable for harsh working conditions

We produce spherical roller bearing mainly through the following steps:

1. Material preparation: Spherical roller bearings typically use high-strength steel as the basic material, and its composition and quality have an important impact on the performance and life of the bearing. The material needs to undergo forging, heat treatment and other processes to ensure that its strength and hardness meet standard requirements.

2. Outer ring manufacturing: The outer ring is one of the important components of the spherical roller bearing, and its manufacturing process includes turning, grinding, heat treatment and other processes. Among them, the grinding process has an important influence on the accuracy and surface quality of the outer ring.

3. Inner ring manufacturing: The manufacturing process of the inner ring is similar to that of the outer ring, and also requires multiple processes such as turning, grinding, and heat treatment. However, the inner ring also needs to undergo gear processing to ensure its matching accuracy and transmission efficiency with the rollers.

4. Roller manufacturing: The roller is the core component of the spherical roller bearing, and its manufacturing process includes forging, turning, grinding, and other processes. The shape and size of the roller have a decisive impact on the bearing's load capacity and accuracy.

5. Assembly: Assemble the outer ring, inner ring, and rollers according to certain matching requirements, while adding lubricating oil or grease and other lubricating materials to form a complete spherical roller bearing.

6. Inspection: Strict quality inspection of the bearing, including testing of appearance, dimensions, hardness, axial and radial clearance, etc.

7.Packaging and shipping: The spherical roller bearing that have undergone quality inspection need to be packaged to protect them from damage. Common packaging materials include cartons, wooden boxes, and pallets. Finally, the products can be shipped to customers by sea, air, or land transportation.

Series: 21000Series、22000Series、22300Series、23100Series、23200Series、24000Series、24100Series、23100Series、23200Series

Mterial:Chrome Steel GCr15

Cages:steel cages, brass cages , nylon cage

Package

A. Industrial Exporting Package with anti-tarnish

paper/Carton/Pallet

B. Individual Paper Box/Carton/Pallet

C: tube package+middle box+outer carton+pallets

D: According to your requirement.

Features:

a、High resistance to impact, vibration

b、Able to self-align

c、Mainly bear big radial load

d、Can bear axial load

Spherical roller bearings are widely used in countless industrial applications, where there are heavy loads, moderate speeds and possibly misalignment. Some common application areas:

a、Gearboxes & Reducers

b、Industrial Fans & Blowers

c、Continuous casting machines

d、Elevators & Escalators

e、Pumps

f、Textile

g、Mining, aggregate & Concrete

h、Pulp and paper processing equipment

i、Marine propulsion and offshore drilling

Spherical roller bearing Product List

| Bearing Model | Dimensions(mm) | Basic Load Rating(KN) | Limiting Speed(r/min) | Weight(KG) | ||||

| d | D | B | Dyn.C | Stat.CO | Grease | Oil | ||

| 22205 | 25 | 52 | 18 | 35.8 | 34.7 | 7700 | 10000 | 0.175 |

| 22206 | 30 | 62 | 20 | 49.4 | 48.7 | 6500 | 8700 | 0.28 |

| 22207 | 35 | 72 | 23 | 68.7 | 70.3 | 5500 | 7400 | 0.45 |

| 22208 | 40 | 80 | 23 | 77.5 | 81.5 | 5000 | 6700 | 0.55 |

| 22209 | 45 | 85 | 23 | 82.3 | 85.9 | 4600 | 6200 | 0.59 |

| 22210 | 50 | 90 | 23 | 87.4 | 93.9 | 4300 | 5700 | 0.64 |

| 22211 | 55 | 100 | 25 | 109 | 118 | 3800 | 5100 | 0.87 |

| 22212 | 60 | 110 | 28 | 130 | 144 | 3500 | 4700 | 1.2 |

| 22213 | 65 | 120 | 31 | 149 | 190 | 3200 | 4200 | 1.55 |

| 22214 | 70 | 125 | 31 | 161 | 208 | 3000 | 4000 | 1.64 |

| 22215 | 75 | 130 | 31 | 167 | 221 | 2900 | 3800 | 1.72 |

| 22216 | 80 | 140 | 33 | 201 | 249 | 2700 | 3500 | 2.12 |

| 22217 | 85 | 150 | 36 | 224 | 285 | 2500 | 3300 | 2.68 |

| 22218 | 90 | 160 | 40 | 246 | 330 | 2300 | 3100 | 3.48 |

| 22219 | 95 | 170 | 43 | 296 | 386 | 2200 | 2900 | 4.21 |

| 22220 | 100 | 180 | 46 | 335 | 453 | 2100 | 2800 | 5.06 |

| 22222 | 110 | 200 | 53 | 411 | 553 | 1900 | 2500 | 7.25 |

| 22224 | 120 | 215 | 58 | 492 | 673 | 1700 | 2300 | 9.1 |

| 22226 | 130 | 230 | 64 | 569 | 789 | 1600 | 2100 | 11.4 |

| 22228 | 140 | 250 | 68 | 658 | 928 | 1400 | 1900 | 14.7 |

| 22230 | 150 | 270 | 73 | 720 | 1020 | 1300 | 1800 | 18.1 |

| 22232 | 160 | 290 | 80 | 885 | 1270 | 1200 | 1600 | 22.9 |

| 22234 | 170 | 310 | 86 | 952 | 1390 | 1100 | 1500 | 28.4 |

| 22236 | 180 | 320 | 86 | 978 | 1450 | 1100 | 1400 | 29.8 |

| 22238 | 190 | 340 | 92 | 1110 | 1730 | 1000 | 1300 | 36.6 |

| 22240 | 200 | 360 | 98 | 1230 | 1930 | 930 | 1200 | 44 |

| 22244 | 220 | 400 | 108 | 1560 | 2400 | 820 | 1100 | 63 |

| 22248 | 240 | 440 | 120 | 1920 | 2990 | 730 | 970 | 79.4 |

| 22252 | 260 | 480 | 130 | 2240 | 3460 | 650 | 870 | 110 |

| 22256 | 280 | 500 | 130 | 2100 | 3380 | 610 | 810 | 114 |

| 22308 | 40 | 90 | 33 | 73.5 | 113 | 4500 | 5600 | 1 |

| 22309 | 45 | 100 | 36 | 95 | 138 | 3800 | 4800 | 1.35 |

| 22310 | 50 | 110 | 40 | 120 | 176 | 3200 | 4300 | 1.85 |

| 22311 | 55 | 120 | 43 | 137 | 199 | 3400 | 4000 | 2.35 |

| 22312 | 60 | 130 | 46 | 166 | 235 | 3000 | 3800 | 2.95 |

| 22313 | 65 | 120 | 48 | 180 | 253 | 2600 | 3400 | 3.55 |

| 22314 | 70 | 150 | 51 | 228 | 311 | 2400 | 3200 | 4.3 |

| 22315 | 75 | 160 | 55 | 255 | 345 | 2200 | 3000 | 5.25 |

| 22316 | 80 | 170 | 58 | 275 | 374 | 2000 | 2800 | 6.2 |

| 22317 | 85 | 180 | 60 | 310 | 420 | 1900 | 2600 | 7.25 |

| 22318 | 90 | 190 | 64 | 365 | 477 | 1800 | 2400 | 8.6 |

| 22319 | 95 | 200 | 67 | 400 | 518 | 1800 | 2400 | 10 |

| 22320 | 100 | 215 | 73 | 475 | 610 | 1700 | 2200 | 13 |

| 22322 | 110 | 240 | 80 | 570 | 725 | 1600 | 2000 | 18 |

| 22324 | 120 | 260 | 86 | 670 | 845 | 1400 | 1800 | 22 |

| 22326 | 130 | 280 | 93 | 780 | 978 | 1300 | 1700 | 28.5 |

| 22328 | 140 | 300 | 102 | 915 | 1130 | 1100 | 1500 | 34.5 |

| 22330 | 150 | 320 | 108 | 1040 | 1270 | 1000 | 1400 | 41.5 |

| 22332 | 160 | 340 | 114 | 1160 | 1380 | 950 | 1300 | 50 |

| 22334 | 170 | 360 | 120 | 1290 | 1540 | 950 | 1300 | 58.5 |

| 22336 | 180 | 380 | 126 | 1460 | 1730 | 900 | 1200 | 69 |

| 22338 | 190 | 400 | 138 | 1560 | 1870 | 850 | 1100 | 80 |

| 22340 | 200 | 420 | 138 | 1730 | 2020 | 850 | 1100 | 92.5 |

| 22344 | 220 | 460 | 145 | 2040 | 2350 | 750 | 950 | 120 |

| 22348 | 240 | 500 | 155 | 2360 | 2710 | 670 | 850 | 155 |

| 23022 | 110 | 170 | 45 | 286 | 478 | 2100 | 2800 | 3.87 |

| 23024 | 120 | 180 | 46 | 229 | 517 | 1900 | 2600 | 4.22 |

| 23026 | 130 | 200 | 52 | 377 | 654 | 1700 | 2300 | 5.99 |

| 23028 | 140 | 210 | 53 | 428 | 737 | 1600 | 2200 | 6.67 |

| 23030 | 150 | 225 | 56 | 467 | 812 | 1500 | 2000 | 8.01 |

| 23032 | 160 | 240 | 60 | 539 | 944 | 1400 | 1900 | 9.9 |

| 23034 | 170 | 260 | 67 | 609 | 1110 | 1300 | 1700 | 13 |

| 23036 | 180 | 280 | 74 | 710 | 1290 | 1200 | 1600 | 17.1 |

| 23038 | 190 | 290 | 75 | 736 | 1370 | 11000 | 1500 | 18.2 |

| 23040 | 200 | 310 | 82 | 890 | 1670 | 1000 | 1400 | 23.4 |

| 23044 | 220 | 340 | 90 | 984 | 1890 | 940 | 1300 | 30.6 |

| 23048 | 240 | 360 | 92 | 1100 | 2170 | 860 | 1100 | 33.8 |

| 23052 | 260 | 400 | 104 | 1330 | 2570 | 760 | 1000 | 49.3 |

| 23056 | 280 | 420 | 106 | 1430 | 2860 | 710 | 950 | 52.9 |

| 23120 | 100 | 165 | 52 | 297 | 493 | 2200 | 3000 | 4.44 |

| 23122 | 110 | 180 | 56 | 346 | 591 | 2000 | 2700 | 5.58 |

| 23124 | 120 | 200 | 62 | 447 | 760 | 1800 | 2400 | 8.09 |

| 23126 | 130 | 210 | 64 | 506 | 826 | 1700 | 2200 | 8.82 |

| 23128 | 140 | 225 | 68 | 561 | 934 | 1500 | 2100 | 10.5 |

| 23130 | 150 | 250 | 80 | 689 | 1230 | 1400 | 1900 | 15.9 |

| 23132 | 160 | 270 | 86 | 796 | 1380 | 1300 | 1700 | 19.9 |

| 23134 | 170 | 280 | 88 | 888 | 1490 | 1200 | 1600 | 21.7 |

| 23136 | 180 | 300 | 96 | 1000 | 1800 | 1100 | 1500 | 27.5 |

| 23138 | 190 | 320 | 104 | 1090 | 2000 | 1000 | 1400 | 34.4 |

| 23140 | 200 | 340 | 112 | 1240 | 2250 | 980 | 1300 | 42.4 |

| 23144 | 220 | 370 | 120 | 1440 | 2700 | 880 | 1200 | 53.2 |

| 23148 | 240 | 400 | 128 | 1630 | 3080 | 790 | 1100 | 65.6 |

| 23152 | 260 | 440 | 144 | 2100 | 3860 | 710 | 940 | 90.8 |

| 23156 | 280 | 460 | 146 | 2140 | 4280 | 660 | 880 | 96.9 |

| 23218 | 90 | 160 | 52.4 | 317 | 459 | 2200 | 3000 | 4.7 |

| 23220 | 100 | 180 | 60.3 | 415 | 599 | 2100 | 2800 | 6.68 |

| 23222 | 110 | 200 | 69.8 | 525 | 786 | 1900 | 2500 | 9.57 |

| 23224 | 120 | 215 | 76 | 583 | 894 | 1700 | 2300 | 11.8 |

| 23226 | 130 | 230 | 80 | 668 | 1030 | 1600 | 2100 | 14 |

| 23228 | 140 | 250 | 88 | 787 | 1230 | 1500 | 1900 | 18.4 |

| 23230 | 150 | 270 | 96 | 924 | 1470 | 1300 | 1800 | 23.8 |

| 23232 | 160 | 290 | 104 | 1030 | 1650 | 1200 | 1600 | 30.1 |

| 23234 | 170 | 310 | 110 | 1150 | 1870 | 1100 | 1500 | 36.5 |

| 23236 | 180 | 320 | 112 | 1190 | 1980 | 1100 | 1400 | 38.6 |

| 23238 | 190 | 340 | 120 | 1410 | 2210 | 1000 | 1300 | 46 |

| 23240 | 200 | 360 | 128 | 1550 | 2610 | 940 | 1300 | 56.4 |

| 23244 | 220 | 400 | 144 | 1880 | 3200 | 830 | 1100 | 79.2 |

| 23248 | 240 | 440 | 160 | 2340 | 3990 | 730 | 970 | 107 |

| 23252 | 260 | 480 | 174 | 2750 | 4640 | 640 | 860 | 140 |

| 23256 | 280 | 500 | 176 | 2690 | 4910 | 610 | 820 | 149 |

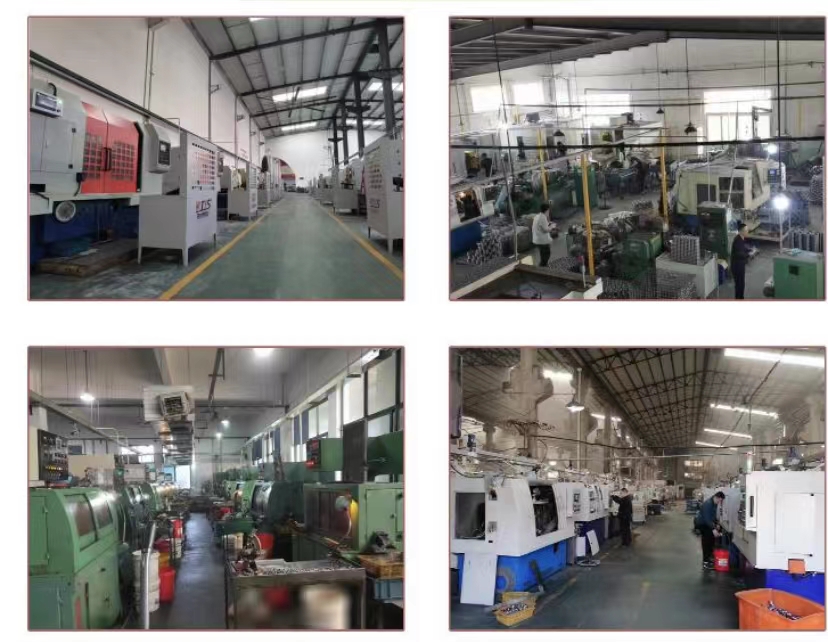

Our Production Workshop

Q1: Are you a trading company or a manufacturer?

A1: We are a manufacturer.We have our own factory ;our type is factory +trade

Q2: How long is your delivery time?

A2: Generally it is 15-20 days, if the goods are in stock, it is 3-7 days, if the goods are not in stock, it depends on the quantity.

Q3: Do you provide samples? Is it free or extra?

A3: Yes, we can provide samples for free, but we don't pay shipping fee.

Q4. How do you control the quality,and what if there is quality problem?

A4: All bearings will be 100% strictly inspected before shipment, including hardness, size, noise, speed, vibration and accuracy. If there is any quality problem, we will replace all faulty products with our shipping cost or refund to you.

Q5:OEM and customized can you accept?

A5: Yes, OEM is accepted, also can be customized for you according to samples or drawings

Q6: What are your shipping conditions.

A6: We can arrange shipping by sea to your nearest seaport or deliver to your doorstep. Air freight is also possible. We can help with all import formalities. It takes about 25-40 days by sea and 3-7 days by air.

Contact: Zhang lianjie

Phone: +86 13771539960

E-mail: jason@jetbearing.com

Whatsapp:+86 13771539960

Add: No.25, Guangtai Industry Park, Xishan District, Wuxi City, Jiangsu Province, China

Contact: Zhang lianjie

Phone: +86 13771539960

E-mail: jason@jetbearing.com

Whatsapp:+86 13771539960

Add: No.25, Guangtai Industry Park,Xishan District, Wuxi City, Jiangsu Province, China

We chat