Self-aligning ball bearings are a type of rolling bearing with self-aligning functionality, consisting of an inner and outer ring, rolling elements (steel balls), and a cage (ball retainer). Unlike other types of rolling bearings, self-aligning ball bearings have a certain degree of self-aligning ability. When there is deviation or misalignment between the shaft and the bearing seat, they can withstand the deviation load by adjusting the balls and cage, ensuring the normal operation of the bearing. Self-aligning ball bearings have the characteristics of large load capacity, smooth rotation, and good wear resistance, and are widely used in the fields of metallurgical equipment, mining machinery, heavy machinery, water pumps, shipbuilding, petrochemical equipment, and others. Additionally, self-aligning ball bearings have advantages such as wear resistance, corrosion resistance, and smooth rotation, which can improve the reliability and service life of mechanical equipment.

Wuxi Jieerte Bearing Co., Ltd. is a professional bearing manufacturer. The company has 20 production lines for bearings, with a daily output of 100,000 sets. Its quality and environmental management system have passed ISO 9001 and ISO 14001 certification. The company has its own brand "JSJET" and also provides OEM services. Our products are known for their high precision, low noise, long service life, and stable performance. They are widely used in various industries such as motors, water pumps, automobile transmissions, motorcycle engines, conveying systems, agricultural machinery, mining equipment, and construction machinery.

What are our advantages?

(1) Advanced production equipment

(2) Strong technical force

(3) High production capacity

(4) Short delivery time

(5) Low MOQ

(6) Strict quality control

(7) Competitive price

(8) ISO9001:2018 certification

We produce self-aligning ball bearing have the following characteristics:

1. Strong self-aligning ability

2. High load-carrying capacity

3. High-speed performance

4.Strong adaptability

5. Good durability

6. Easy installation

7. Wide applicability

We produce self-aligning ball bearing mainly through the following steps:

1. Material preparation: The material used for Self-aligning ball bearings is usually high-quality steel, such as GCr15. During the production process, the material undergoes chemical composition analysis, metallographic examination, hardness testing, and other procedures to ensure that the quality of the material meets the requirements.

2. Cutting processing: The selected raw material is cut to the specified length and preliminarily shaped for subsequent processing.

3. Heat treatment: To improve the hardness, strength, and toughness of the steel, it is subjected to heat treatment. Quenching and tempering processes are commonly used to achieve the desired performance indicators.

4. Cold processing: The material after heat treatment requires cold processing, which mainly includes processing the steel balls, stamping the cage, and turning the inner and outer rings. Common cold processing techniques include turning, grinding, gear grinding, and gear rolling.

5. Precision processing: The various components that have undergone cold processing are precision machined, including grinding the inner and outer rings and the cage, and polishing the balls to ensure the precision and quality of the bearing.

6. Assembly: The precision-machined inner and outer rings, cage, and balls are assembled using special machines and adjusted and lubricated. During assembly, each part's size and relative position must be strictly controlled to ensure the performance and service life of the Self-aligning ball bearings

7. Inspection: After assembly, the Self-aligning ball bearings need to be inspected. Common inspection techniques include visual inspection, dimension measurement, torque testing, noise testing, and more. Only spherical roller bearings that have passed rigorous inspection can be sold.

8. Packaging and shipping: The self-aligning ball bearings that has undergone quality inspection need to be packaged to protect them from damage. Common packaging materials include cartons, wooden boxes, and pallets. Finally, the products can be shipped to customers by sea, air, or land transportation.

Series: 1200Series,1300eries,2200Series,2300Series

Materail:Chrome Steel GCr15

Cages:steel cages, brass cages

Types: plain ,taper

Sealing/Shield: Z, ZZ, RS, 2RS,Opean

Quality: ABEC-1(P0)、ABEC-3(P6)、ABEC-5(P5)

Noise Level: Z1V1、Z2V2、Z3V3、Z4V4

Application: precision instruments, low-noise motors, automobiles, motorcycles, metallurgy, rolling mills, mining, petroleum, paper, cement

Package

A. Industrial Exporting Package with anti-tarnish

paper/Carton/Pallet

B. Individual Paper Box/Carton/Pallet

C: tube package+middle box+outer carton+pallets

D: According to your requirement.

| Bearing Model | Dimensions(mm) | Basic Load Rating(N) | Limiting Speed(r/min) | Weight(KG) | ||||

| d | D | B | Dyn.C | Stat.CO | Grease | Oil | ||

| 1200 | 10 | 30 | 9 | 5480 | 1200 | 25000 | 28000 | 0.034 |

| 1201 | 12 | 32 | 10 | 5550 | 1250 | 22000 | 26000 | 0.04 |

| 1202 | 15 | 35 | 11 | 7480 | 1750 | 19000 | 23000 | 0.049 |

| 1203 | 17 | 40 | 12 | 7900 | 2020 | 18000 | 21000 | 0.073 |

| 1204 | 20 | 47 | 14 | 9950 | 2650 | 16000 | 18000 | 0.116 |

| 1205 | 25 | 52 | 15 | 12000 | 3300 | 13000 | 15000 | 0.14 |

| 1206 | 30 | 62 | 16 | 15800 | 4700 | 11000 | 13000 | 0.22 |

| 1207 | 35 | 72 | 17 | 15800 | 5080 | 9800 | 11000 | 0.32 |

| 1208 | 40 | 80 | 18 | 19200 | 6400 | 8700 | 10000 | 0.415 |

| 1209 | 45 | 85 | 19 | 21800 | 7320 | 7800 | 9200 | 0.465 |

| 1210 | 50 | 90 | 20 | 22800 | 8080 | 7100 | 8300 | 0.531 |

| 1211 | 55 | 100 | 21 | 26800 | 10000 | 6400 | 7600 | 0.705 |

| 1212 | 60 | 110 | 22 | 30200 | 11500 | 6000 | 7000 | 0.9 |

| 1213 | 65 | 120 | 23 | 31000 | 12500 | 5500 | 6500 | 1.15 |

| 1214 | 70 | 125 | 24 | 34500 | 13500 | 5100 | 6000 | 1.24 |

| 1215 | 75 | 130 | 25 | 38800 | 15200 | 4800 | 5600 | 1.39 |

| 1216 | 80 | 140 | 26 | 39500 | 16800 | 4500 | 5300 | 1.7 |

| 1217 | 85 | 150 | 28 | 48800 | 20500 | 4200 | 5000 | 2.06 |

| 1218 | 90 | 160 | 30 | 56500 | 23200 | 4000 | 4700 | 2.59 |

| 1219 | 95 | 170 | 32 | 63500 | 27000 | 3700 | 4400 | 3.1 |

| 1220 | 100 | 180 | 34 | 67400 | 28400 | 3500 | 4200 | 3.7 |

| 1300 | 10 | 35 | 11 | 7220 | 1620 | 23000 | 27000 | 0.058 |

| 1301 | 12 | 37 | 12 | 9420 | 2120 | 20000 | 24000 | 0.067 |

| 1302 | 15 | 42 | 13 | 9500 | 2280 | 17000 | 21000 | 0.094 |

| 1303 | 17 | 47 | 14 | 12500 | 3180 | 16000 | 19000 | 0.13 |

| 1304 | 20 | 52 | 15 | 12500 | 3380 | 14000 | 17000 | 0.165 |

| 1305 | 25 | 62 | 17 | 17800 | 5050 | 12000 | 14000 | 0.255 |

| 1306 | 30 | 72 | 19 | 21500 | 6280 | 10000 | 12000 | 0.385 |

| 1307 | 35 | 80 | 21 | 25000 | 7950 | 8800 | 10000 | 0.51 |

| 1308 | 40 | 90 | 23 | 29500 | 9500 | 7800 | 9200 | 0.715 |

| 1309 | 45 | 100 | 25 | 38000 | 12800 | 7000 | 8200 | 0.955 |

| 1310 | 50 | 110 | 27 | 43200 | 14200 | 6400 | 7500 | 1.2 |

| 1311 | 55 | 120 | 29 | 51500 | 18200 | 5800 | 6800 | 1.6 |

| 1312 | 60 | 130 | 31 | 57200 | 21200 | 5400 | 6300 | 1.95 |

| 1313 | 65 | 140 | 33 | 61800 | 22800 | 4900 | 5800 | 2.42 |

| 1314 | 70 | 150 | 35 | 74500 | 27500 | 4600 | 5400 | 3 |

| 1315 | 75 | 160 | 37 | 79000 | 29800 | 4300 | 5000 | 3.55 |

| 1316 | 80 | 170 | 39 | 86700 | 31400 | 4000 | 4700 | 4.17 |

| 1317 | 85 | 180 | 41 | 97800 | 37800 | 3800 | 4500 | 5 |

| 1318 | 90 | 190 | 43 | 115000 | 42000 | 3600 | 4200 | 5.8 |

| 1318 | 90 | 190 | 43 | 115000 | 42000 | 3300 | 3900 | 5.8 |

| 1319 | 95 | 200 | 45 | 132000 | 50800 | 3200 | 3700 | 6.7 |

| 1320 | 100 | 215 | 47 | 141000 | 55000 | 13000 | 15000 | 8.3 |

| 2200 | 10 | 30 | 14 | 8000 | 1800 | 9500 | 12000 | 0.048 |

| 2201 | 12 | 32 | 14 | 8400 | 1900 | 8500 | 10000 | 0.052 |

| 2202 | 15 | 35 | 14 | 8600 | 2000 | 7500 | 9000 | 0.056 |

| 2203 | 17 | 40 | 16 | 10400 | 2500 | 6700 | 8000 | 0.087 |

| 2204 | 20 | 47 | 18 | 16400 | 4100 | 6000 | 7000 | 0.13 |

| 2205 | 25 | 52 | 18 | 15200 | 3900 | 5300 | 6300 | 0.16 |

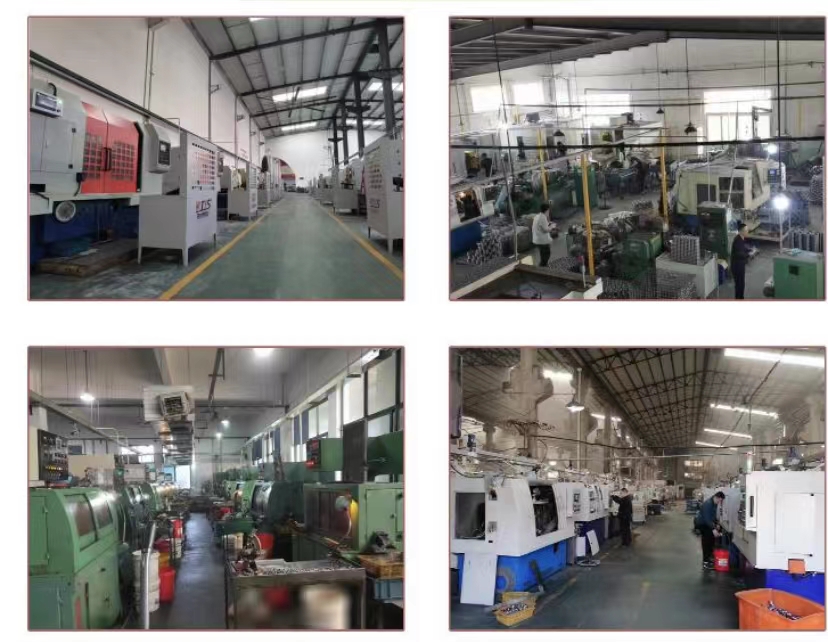

Our Production Workshop

Q1: Are you a trading company or a manufacturer?

A1: We are a manufacturer.We have our own factory ;our type is factory +trade

Q2: How long is your delivery time?

A2: Generally it is 15-20 days, if the goods are in stock, it is 3-7 days, if the goods are not in stock, it depends on the quantity.

Q3: Do you provide samples? Is it free or extra?

A3: Yes, we can provide samples for free, but we don't pay shipping fee.

Q4. How do you control the quality,and what if there is quality problem?

A4: All bearings will be 100% strictly inspected before shipment, including hardness, size, noise, speed, vibration and accuracy. If there is any quality problem, we will replace all faulty products with our shipping cost or refund to you.

Q5:OEM and customized can you accept?

A5: Yes, OEM is accepted, also can be customized for you according to samples or drawings

Q6: What are your shipping conditions.

A6: We can arrange shipping by sea to your nearest seaport or deliver to your doorstep. Air freight is also possible. We can help with all import formalities. It takes about 25-40 days by sea and 3-7 days by air.

Contact: Zhang lianjie

Phone: +86 13771539960

E-mail: jason@jetbearing.com

Whatsapp:+86 13771539960

Add: No.25, Guangtai Industry Park, Xishan District, Wuxi City, Jiangsu Province, China

Contact: Zhang lianjie

Phone: +86 13771539960

E-mail: jason@jetbearing.com

Whatsapp:+86 13771539960

Add: No.25, Guangtai Industry Park,Xishan District, Wuxi City, Jiangsu Province, China

We chat